ACS

Angelantoni Test Technologies 集團完整資料

Angelantoni Test Technologies group of companies at this web site: www.att-testing.com

ACS產品

ACS products: www.acstestchambers.com where you will find specific pages both for standard and customized products.

ACS 主要標準試驗箱的型錄資料:ACS main standard chambers:

Climatic and thermostatic chambers Discovery My

Vibration test chambers AV - AV T

Halt and Hass chambers UHS

Corrosion test chambers DCTC

Thermal shock test chambers CST/CSTL

Modular walk-in chambers WZH - WZT

Solar/Photovoltaic panel test chambers PV

Calorimeters to test Energy efficiency on air conditioners

特殊規格客製 化產品: For customized products:

Battery test chambers (click here)

Aerospace, Aeronautics and Defense applications (click here)

Case history brochures:

EURAC Thermal Transmittance test chambers for Construction Industry components (click here)

Tunnel ovens for thermal treatment (click here)

ESA/ESTEC Thermal Control Unit Refurbishment (click here)

Automotive applications (click here)

Compact Climatic Chambers (60-200 L)

Quality and performance are continually put to the test, from the warmest to the coldest climates, from the effect of corrosive agents to stresses during packaging, transport and storage. These factors could lead to breakage, failures or a reduction in product life. ACS Climatic Chambers are designed to support our customers in the development of a product that performs at its full potential.

The Compact Line of ACS Climatic and Thermostatic Chambers combines performance and flexibility. Their limited size and ability to do climatic and thermostatic tests makes them the ideal solution for those who do not have enough space for a large test laboratory.

The carrying out of climatic and thermostatic tests helps to reveal potential defects before the specimen passes into production, ensuring:

- A product of tested quality

- Savings on design costs

- Lower maintenance costs

- More satisfied customers

Discovery My Climatic Chambers

ACS Discovery My Climatic and Thermostatic Chambers guarantee high performance, a generous standard configuration and a large number of accessories for adapting to all the requests of our customers.

- The test helps to reveal potential defects before the specimen passes into production, ensuring:

- A product of tested quality

- Savings on design costs

- Lower maintenance costs

- More satisfied customers

Discovery My Climatic Chambers for stability tests

Discovery My Climatic Chambers for stress screening

Discovery My Climatic Chambers for severe stress screening

The Discovery My ESS climate chambers were developed to help manufacturers detect product and manufacturing defects. Performing a stress screening test can reveal "infant mortality" and the failures of defective product components. These problems may occur after delivery of the product and also during the warranty period.

Using a climatic chamber for stress screening tests reduces:

- Field defects

- Warranty costs

- Time to market

- Infant mortality in the field

- Manufacturing costs

Energy saving climatic chambers, Flower®

Climatic Chambers for solar light tests

The ACS Climatic and Thermostatic Chambers for solar simulation tests allow the specimen to be subjected to tests that simulate the effects of sunlight. Performance, insulation, noise, and resistance to physical and mechanical losses are just some of the parameters tested. Exposure to sunlight can in fact damage the products, reduce their performance and shorten their service life.

The Discovery My range for solar simulation tests is available in the standard, energy saving and 5K/min versions, in different volumes, to meet every customer's needs

Discovery My Climatic Chambers with air conditioning unit kit

The ACS Climatic and Thermostatic Chambers with air treatment units make it possible to simulate the desired temperature and humidity inside the chamber and to convey the treated air to the inside of an external unit in which the specimen to be tested has been placed.

The Discovery My range with air treatment units is available in the standard, stability test, energy saving and 5K/min and stress screening test versions, in different volumes, to meet every customer's needs.

Discovery My Climatic Chambers with fast cooling kit by LN2

ACS Discovery My Climatic and Thermostatic Chambers cooled with LN2 are used when high cooling values are required. In these cases, liquid nitrogen (LN2) is injected, which allows a cooling rate of over 30K/min. These tests are especially useful for investigating the reaction of electronic components used in aeronautical and aerospace applications, which undergo sudden changes in their working environment within a few seconds.

- an inverter that controls the compressor speed and allows adjustment of the compressor power for different work needs

- The test helps to reveal potential defects before the specimen passes into production, ensuring:

- A product of tested quality

- Savings on design costs

- Lower maintenance costs

- More satisfied customers

Discovery My Climatic Chambers for Battery tests

ACS Climatic and Thermostatic Chambers make it possible to conduct tests in controlled temperature and humidity conditions similar to those in which the battery will operate during its service life.

Battery charge and discharge testing cycles are a key activity in laboratories doing battery testing. The instruments used for these tests often subject batteries to demanding and long-lasting testing cycles.

The Discovery My range for battery tests is available in the standard, stability test, energy saving and 5K/min and stress screening test versions, in different volumes, to meet every customer’s needs.

Air to Air Thermal Shock Chambers

Climatic chambers for thermal shock tests are used to subject the specimen to strong shocks by passing it suddenly and repeatedly from a hot temperature zone to a cold one. The specimen can cool or heat at different rates at different points, depending on the material. If exposure to repeated cycles cause large expansions and contractions in volume, the material could undergo strong mechanical stresses and sometimes break.

Liquid to Liquid thermal shock chambers

Climatic chambers for "liquid-to-liquid" thermal shock tests are used to test electronic components with strong shocks by passing them suddenly and repeatedly from a tank with hot liquid to one with cold liquid. The liquid used, whose physical state remains unchanged within the chamber temperature range, subjects the DUT (Device Under Test) to a strong shock that tests its resistance.

Corrosion test chambers

Corrosion is a chemical or electrochemical reaction between a material and its environment. This process causes the deterioration of the product and the loss of its initial characteristics.

Climatic chambers for corrosion testing can help predict the resistance of materials in order to estimate the life cycle of the components, compare different products and evaluate the behavior of a coating in a specific corrosive environment.

Vibration test chambers

Using a climatic chamber for vibration tests allows the specimen to be subjected to a combination of different tests, such as: vibrations, temperature variations and climatic variations. This type of test is used to evaluate the resistance of components and equipment to combined climatic and mechanical stresses that can affect performance in conditions of normal use. Automotive and aerospace components are among the main categories of products that must be subjected to such tests to ensure reliability and safety for users.

- Machine group

- Air treatment units

- User Interface

- Panel structure

Altitude test chambers

Modular walk-in chambers

ACS Prefabricated Modular Chambers combine the guarantee of reliable and reproducible tests with the advantage of an easily configurable product, quick to assemble and easy to renew in case of future needs not considered at the time of purchase. The project is based on the four standard elements of a prefabricated chamber to be composed and coupled to create the most suitable configuration for the customer's needs:

- Machine group

- Air treatment units

- User Interface

- Panel structure

Halt and Hass test chambers

Rain test Chambers

Products are exposed to several atmospheric agents and to changes in temperature and humidity during their service life. Rain also causes a high degree of deterioration.

The rain test chambers carry out tests on products exposed outdoors, even if not regularly, such as lighting equipment, satellite dishes, and vehicles. These products must be able to function reliably while withstanding various rain intensities.

Sand/ Dust test chambers

Products are exposed to several atmospheric agents and to changes in temperature and humidity during their service life. Sand also produces a high degree of deterioration.

ACS chambers for sand and dust tests are able to reproduce all the conditions included in the standards that require continuous ventilation (DIN 40046, MIL-STD 331 AND MIL-STD 810 C), dust drop tests (DIN 40052) and tests with irregular whiff of compressed air (SAE J 575).

Calorimeters

Climate change has brought about a changing of seasons characterized by increasingly extreme temperatures and has led to an increasing use of air conditioners, which have now become a commonly used appliance. These have a strong effect on the energy balance, leading to the search for increasingly efficient and sustainable solutions.

ACS has developed a line of standard calorimeters that cover the testing and certification needs for home air conditioning systems, both split and monoblock types, and for testing air conditioners in the automotive industry.

Solar/ Photovoltaic module test chambers

Standard thermal vacuum chambers (TVC)

Customized thermal shock chambers

Climatic chambers for thermal shock tests are used to subject the specimen to strong shocks by passing it suddenly and repeatedly from a hot temperature zone to a cold one. The specimen can cool or heat at different rates at different points, depending on the material. If exposure to repeated cycles cause large expansions and contractions in volume, the material could undergo strong mechanical stresses and sometimes break.

In addition to the standard line, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Customized corrosion test chambers

Corrosion is a chemical or electrochemical reaction between a material and its environment. This process causes the deterioration of the product and the loss of its initial characteristics.

Climatic chambers for corrosion testing can help predict the resistance of materials in order to estimate the life cycle of the components, compare different products and evaluate the behavior of a coating in a specific corrosive environment.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

The models of the standard line of ACS vibration test chambers are described in detail in the technical data sheet.

Customized battery test chambers

ACS Climatic and Thermostatic Chambers make it possible to conduct tests in controlled temperature and humidity conditions similar to those in which the battery will operate during its service life. Battery charge and discharge testing cycles are a key activity in laboratories doing battery testing. The instruments used for these tests often subject batteries to demanding and long-lasting testing cycles.

In addition to the standard line, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Customized altitude test chambers

Climatic chambers for altitude tests are used to reproduce the operating conditions of components or products that operate in environments where the atmospheric pressure decreases over time. When carrying out tests in the aeronautics industry, an effective combined control of temperature and pressure must be guaranteed in order to simulate the exact altitude above sea level. Humidity control is also necessary in some cases

In addition to the standard line of altitude chambers, ACS can provide special chambers for high vacuum tests, combined vibration tests, icing tests, and vacuum shock tests, according to customer specifications or standards such as MIL-STD 810 G and RTCA-DO-160.

Customized vibration test chambers

Using a climatic chamber for vibration tests allows the specimen to be subjected to a combination of different tests, such as: vibrations, temperature variations and climatic variations. This type of test is used to evaluate the resistance of components and equipment to combined climatic and mechanical stresses that can affect performance in normal usage conditions. Automotive and aerospace components are among the main categories of products that must be subjected to such tests to ensure reliability and safety for users.

ACS can supply chambers according to the specific needs of customers, suitable for any product volume to be tested, and that perform various test conditions with both vertical and horizontal vibrations, very rapid cooling rates, or specific standards such as the MIL-STD 810 G standards.

The models of the standard line of ACS vibration test chambers are described in detail in the technical data sheet.

Customized sand/ dust test chambers

Products are exposed to several atmospheric agents and to changes in temperature and humidity during their service life. Sand also produces a high degree of deterioration.

ACS chambers for sand and dust tests are able to reproduce all the conditions included in the standards that require continuous ventilation (DIN 40046, MIL-STD 331 AND MIL-STD 810 C), dust drop tests (DIN 40052) and tests with irregular whiff of compressed air (SAE J 575).

In addition to the standard line, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Customized solar simulation test chambers

The ACS Chambers for solar simulation tests allow the specimen to be subjected to tests that simulate the effects of sunlight. Performance, insulation, noise, and resistance to physical and mechanical losses are just some of the parameters tested. Exposure to sunlight can in fact damage the products, reduce their performance and shorten their service life.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

The models of the standard line of ACS solar light test chambers, described in detail in the technical data shee, are available in the standard, energy saving and 5K/min versions.

Customized rain test chambers

Products are exposed to several atmospheric agents and to changes in temperature and humidity during their service life. Rain also causes a high degree of deterioration.

The rain test chambers carry out tests on products exposed outdoors, even if not regularly, such as lighting equipment, satellite dishes, and vehicles. These products must be able to function reliably while withstanding various rain intensities.

In addition to the standard line, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Customized photovoltaic module test chambers

The problem of global warming has helped to increase attention to the protection of the planet and the search for renewable energy sources, among which solar energy is considered one of the most promising. In this sector, solar panels are among the most used tools to "capture" solar energy and are therefore at the center of severe tests to study wear and aging.

In addition to the standard line, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Customized thermal vacuum chambers (TVC)

The ACS climatic chambers for testing in the aeronautics and aerospace industry reproduce the environmental conditions typical of the landing/ take-off stages and travel in space, guaranteeing high standards of reliability and quality for the products that pass the tests.

Space simulators (TVC - Thermal Vacuum Chambers), that artificially reproduce the real working conditions of satellites and spacecraft equipment reaching pressure values down to 10-8 mbar, represent one of the highest achievements of ACS technology allowing it to become leader in the strategic Aerospace sector at international level.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

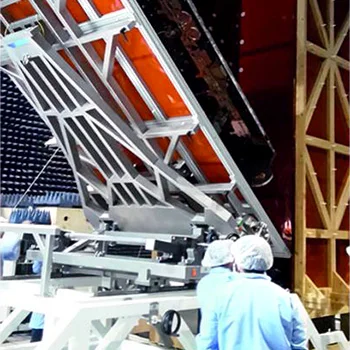

Chambers for environmental stress screening on antennas and satellite components

The ACS climatic chambers for testing in the aeronautics and aerospace industry reproduce the environmental conditions typical of the landing/ take-off stages and travel in space, guaranteeing high standards of reliability and quality for the products that pass the tests.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Chambers for thermal tests and radio frequency measurements on antennas

Combined vacuum/ vibration test chambers

Environmental chambers for controlling pressure values to simulate altitude above sea level are a fundamental tool in the aviation industry. Over the years the tests required for the development and qualification of new equipment have become increasingly complex and integrated.

The need to have several parameters under control at the same time and to be able to simulate extreme conditions has made the climatic chamber for altitude tests a necessary tool.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Climatic Dyno chambers

The climatic chambers coupled with road dynamometers are produced by ACS in collaboration with leading companies in dynamometer technology.

This type of climatic chamber makes it possible to test the efficiency of the engine compartment under climatic stress during the typical working cycles of a vehicle according to international automotive standards. If an appropriate exhaust gas collection and analysis system is installed, the equipment can be used to perform emission tests.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Engine test chambers

4 - POSTER TEST CHAMBERS

ACS works in partnership with leading manufacturers of road simulation actuators in order to offer integrated systems that make it possible to simulate different road surface conditions together with a wide range of environmental conditions.

This type of climatic chamber can be used to test not only cars, but also agricultural and construction vehicles, scooters and motorcycles.

For demanding acoustic performance testing, a technologically advanced solution is applied inside the climatic chamber to reduce the noise of air circulation.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

VT Shed

ACS VT SHED chambers are produced in collaboration with specialized companies. They can be used for HC emissions testing in tanks of vehicles filled with fuel or other components in accordance with EPA, ECE and other standards.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Climatic Wind tunnels

A climatic wind tunnel is essential to accelerate the development stage, increase vehicle performance, and improve environmental sustainability, driver safety, comfort and fuel consumption.

The use of a climate wind tunnel can shorten the time from product engineering to market launch.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Airbag test chambers

ACS chambers for testing airbag systems are designed to perform the standard tests required by the main regulations. Using high speed cameras, it is possible to record every moment of the airbag activation. The chamber can be provided with a high-speed door opening and closing system for rapid deployment of the test specimen on a dedicated frame. Alternatively, multiple windows can be installed on one side of the camera and high-speed cameras can be installed right in front of them. Temperature and humidity parameters are set inside the chamber to achieve the desired conditions.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Pedal test chambers

ACS chambers can be integrated with an automatic pedal shifting system. Special safety measures have been specially designed to avoid risks related to operator exposure to moving parts and extreme temperatures.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Calorimeters to test the efficiency of air conditioning systems

Climate change has brought about a changing of seasons characterized by increasingly extreme temperatures and has led to an increasing use of air conditioners, which have now become a commonly used appliance. These have a strong effect on the energy balance, leading to the search for increasingly efficient and sustainable solutions.

In addition to the standard line of calorimeters, ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Climatic chambers to test home radiators

The need to reduce the energy used for home heating requires careful and accurate experimental testing on the different usage conditions and the various heat terminal units. The ACS chamber not only provides accurate measurements in compliance with the EN 442 European standard, but allows for the additional considerations necessary to determine more realistic evaluation indexes for the different types of heat terminal units.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Climatic chambers for transmittance tests on building components

The purpose of this specific project is the design and construction of a testing system for building facade elements, from walls, roofs, and windows to louvered doors, to examine their thermal behavior in both winter and summer and in stationary and dynamic climatic conditions.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

Tunnel ovens for heat treatments

Consistently with its mission of expanding its product range through continuous Research & Development, Angelantoni Test Technologies has strengthened its contribution to environmental sustainability through the manufacturing of tunnel ovens used for the stabilization and coating treatment of Receiver Tubes for thermodynamic solar power plants.

ACS is able to offer customized solutions thanks to its more than 60 years of experience in designing customized environmental simulation chambers, its technical know-how and the close attention given to the requests of all our customers.

建議您可同時參考以下相關產品目錄。