WORLDWIDE

Home

/

Product Line

Vibration Tester

Vibration Tester is one of our main products, featuring its high quality and excellent performance. KING DESIGN is committed to our long-term strategy of continuously releasing innovative Vibration Tester and offering machinery & industrial supplies solutions in a global market together with our partners. Having a question about KING DESIGN or want to know more details about Vibration Tester? Email or call our Sales Support Team about your questions before purchasing.

E.S.S(Environmental Stress Screening)

E.S.S system could find most potential and hiding defects earlier by checking the physical property of allmaterials and components, and make use of their nature response under Environmental Stress. Through our screening will to pick out all potential and hiding defects in advance and improving the product's reliability inling. It benefits the manufacturer and customer mutually.

KD-9363-ED-4S1R

Multifunctional Vibration System

Vibration testing is applied to confirm the reliability and screen out of the non-performing products prior to ship out of the factory; and to assess the non-performing failure analysis;expecting to become high standard, high reliability products.

KD-9363-EM

Standard Electromagnetic Vibrator

The purpose of vibration testing is to make a series of controllable vibration simulation in lab, no matter generated by natural or man-made vibration environment; such as waves, tidal flaps, wind, earthquake or rain and so on. It is to test if the product is capable of sustaining the vibration environment exerted from transporting or usage along its effective life cycle; and certify the standard of design & functional requirement of product. The value of vibration testing is to confirm the reliability of products and effectively screen out the bad products in factory; avoiding damages occurred at arrival; and to assess the failure analysis on the non-performing products; expecting to reach a high standard, high-reliability products. The vibration test stresses on the continuity and fatigue; and contributes to the understanding of product’s status under vibration circumstance in a normal environment; and avoids the product’s unpredictable damage caused under certain vibrating frequency for a long time.

9363-LN-100

Large-Displacement Low-Frequence Vibration System

TYPE: 9363-LN-100

ROTATION RATE:120 ~ 300 r.p.m

FREQUENCY RANGE:2 ~ 5 Hz

ROTATION RATE:120 ~ 300 r.p.m

FREQUENCY RANGE:2 ~ 5 Hz

9363-PC-ESS

Press-type Vibration Tester

MD analyzer

MD Analyzer

Product Function

Operation Display

32dot*128dot/STN-LCD+LED

Use knot and SET.ESC-SW to choose menu

USB memory/printer communication port

OK

No voltage A contact, contact capacity

Only less than 1 A 30 VDC or 0.5 A125 VAC resistive load

Instant Disconnection

DC 12 V±10%1A/100mA /10mA±10%

1A:1Ω~50Ω10%

100mA: 5~500±10%

10mA: 50~5kΩ±10%0.1us~99.9us

Product Function

Operation Display

32dot*128dot/STN-LCD+LED

Use knot and SET.ESC-SW to choose menu

USB memory/printer communication port

OK

No voltage A contact, contact capacity

Only less than 1 A 30 VDC or 0.5 A125 VAC resistive load

Instant Disconnection

DC 12 V±10%1A/100mA /10mA±10%

1A:1Ω~50Ω10%

100mA: 5~500±10%

10mA: 50~5kΩ±10%0.1us~99.9us

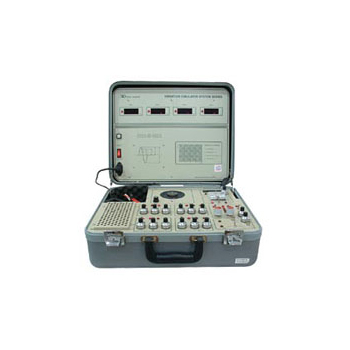

KD-9363

Transportation Vibration Simulator

Transportation vibration simulator is mainly used to check the product encountered in various vibration environmental of manufacture, assemble and install, transit and usage process. Especially all types of transportation vehicle. Common transport is road, railway, sea, air, etc.

To identify whether the product have the anti-vibration capability to endure transportation environment and avoid arrival damage and harm the company reputation. It also can analyze the specimen structure and study its dynamic character.

To identify whether the product have the anti-vibration capability to endure transportation environment and avoid arrival damage and harm the company reputation. It also can analyze the specimen structure and study its dynamic character.

KD-9363-ML

Heavy duty of Transportation Vibration Simulator

Transportation vibration simulator is mainly used to check the product encountered in various vibration environmental of manufacture, assemble and install, transit and usage process. Especially all types of transportation vehicle. Common transport is road, railway, sea, air, etc.

To identify whether the product have the anti-vibration capability to endure transportation environment and avoid arrival damage and harm the company reputation. It also can analyze the specimen structure and study its dynamic character.

To identify whether the product have the anti-vibration capability to endure transportation environment and avoid arrival damage and harm the company reputation. It also can analyze the specimen structure and study its dynamic character.

KD-9363EM-Analysis shaker

Modal Analysis Shaker

This machine can test the structural properties of materials, manual fine-tuning vibration frequency can perform single-point resonance search and presence; after shaking, capture resonance excitation modal analysis data for future use.

Our adherence to the timely and safe delivery of our fine quality Vibration Tester has enabled us to maintain a long-lasting relationship with our existing clients. The Vibration Tester that we offer maintains unquestionably reliable and fool-proof standards. We provide services to quench the market demand with full competency, thereby treating our customers with complete satisfaction and convenience. We have the expertise and longevity that leads to customer satisfaction with our work. You will not go wrong if you choose us for your Vibration Tester needs.