WORLDWIDE

Home

/

Product Line

PV Test Equipment

KING DESIGN provides a range of PV Test Equipment services for companies seeking to expand our business in Taiwan and abroad. Quality is the only business policy of our organization that segregated us from others. To assure this in each set of PV Test Equipment products, we follow a strict policy from sourcing raw material to the final stage of delivery. We operate worldwide, configure, service products, and also provide logistics support to deliver products and services competitively.

Class AAA Steady State Solar Simulator

- Lamp average life 25,000 hours (We offer 1 year warranty including lamps)!

- Spectrum Mis-match Class A, without filter!

- Irradiance almost no decay within 10,000 hours!

- Spectrum maintains stable during power adjustment!

Dynamic Mechanic Loading Tester

- Complies with IEC 61646, IEC 61215 mechanical load test specification.

- Air pressure is adjustable, output range is from 2400pa to 5400pa ±5% .

- Maximum measurement range: 220 x 260 cm.

- Apparatus structure material:aluminum-extruded.

- Fixtures and holders can be customized design for requirement of testing module.

- Manual operation is simple; manual maintenance is easy.

4 in 1 Hail Tester

| As a fact that solar panels or related equipment are placed under direct sunlight outdoors without shelter, they are vulnerable to the effects of climate change causing aging and damage; such as when under hail strike, solar panels or equipment are easy to be damaged from hail hits.. This tester can simulate the impact of hail falling onto your products; and you can adjust the products to facilitate them with the best quality and reliability in the market. |

UV Aging System

- Comply with IEC 61215, IEC 61646 UV Preconditioning Test Specification

- Radiation intensity is linear adjustable; the intensity deviation is guaranteed within ±15% on the testing surface

- Test cabinet is equipped with timer controller in a time range of 0~9999 hr, as well as time accumulating and power-shutdown data-saving ability

- Using the standard PT-100 membrane thermo-transmitter to accurately control temperature in testing process

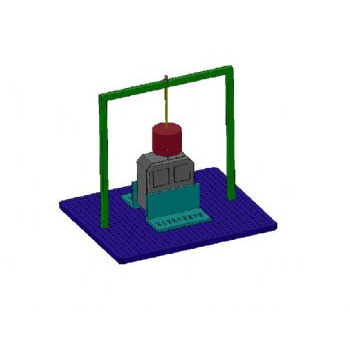

Module Breakage Tester

- Destruction System Hardware:

- est rack system: support, shielding cover, crane & fixed wall.

- Hit bag: FRP bag; 45kg of No.7.5 lead pills; hook, sleeve and hoisting ring.

- Attachment: electronic scale, stopwatch, digital caliper

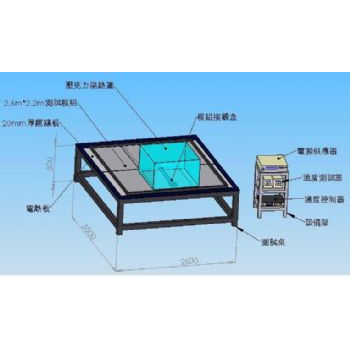

Bypass Diode Thermal Test System

1. Power: the heating board control panel uses 220V single-phase power.

2. Power consumption: 1.0KVA, 1000W(Max)

3. Volt: 220VAC

4. Current: 4.5A

5. Heating board: one controller per board

6. Power rate: room temperature raise to 75°C± 5°C within one minute.

7. Heating board dimension: 500mm x 1,000mm

8. 6-sheet electrical heating boards test: used to test the 2,200mm x 2,600mm module. It can be customer-designed.

9. The length of board power cable and thermal sensor cable shall exceed 3,000mm.

10. To get uniform heating effect, the electrical board is sandwiched by 2mm aluminum sheets at both sides of board.

2. Power consumption: 1.0KVA, 1000W(Max)

3. Volt: 220VAC

4. Current: 4.5A

5. Heating board: one controller per board

6. Power rate: room temperature raise to 75°C± 5°C within one minute.

7. Heating board dimension: 500mm x 1,000mm

8. 6-sheet electrical heating boards test: used to test the 2,200mm x 2,600mm module. It can be customer-designed.

9. The length of board power cable and thermal sensor cable shall exceed 3,000mm.

10. To get uniform heating effect, the electrical board is sandwiched by 2mm aluminum sheets at both sides of board.

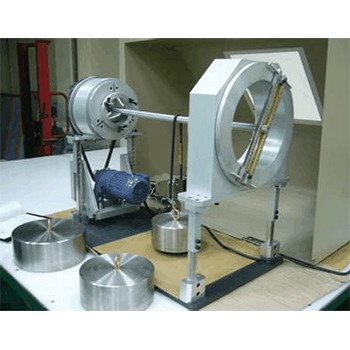

Robustness of Terminations Tester

- Cable test length is 450mm.

- Pull the leading wire by 4.08kg in 170 o of angle.

- X-axle: from 170o right swinging to 170o left.

- Y-axle: from 170o up swinging to 170o down.

- Z-axle: pull at 170 o and spin.

Wet Leakage Current Test

The outdoor solar module will endure the erosion of rain, fog, snow and sandstorm. To make sure that solar module will not wet leakage current accident and tolerate huge load pressure in such harsh conditions, we adopt wet leakage current to simulate the above weather conditions.

Thermal Cycling and Humidity-Freeze Test

- 10.4" TFT LCD, touch-type Chinese/English display controller.

- Temperature/humidity setting procedure, LCD curve display device (set to “curve display”).

- Chinese/English/LCD operation/troubleshoot/guiding window.

- State-of-the-art intelligent auto-dispatch “heat load value” coolant servo valve flowrate algorithm control.

Damp-Heat Tester

- Technical index:

- Power: 380V, 3-, 50/60HZ 110A

- Temperature range: 50°C~120°C

- Humidity range: 20%~95% RH

- Accuracy: 1) temperature ± 0.3°C;2) humidity ± 2.5% RH

- Uniformity: 1) temperature ± 2.0°C;2) humidity ± 3.0% RH

- Uniformity test: measured at T=85°C, RH=85%; set 9 points for temperature measurement and 2 points for humidity.

- Inner wall is above 50 cm; within 20 min after temperature/humidity meets the setting value, the distribution uniformity of temperature/humidity can meet the aforesaid requirement.

Terminal Box Knock Out Tester

Since the solar panels and power junction box are exposed to the sun and rain, therefore, if junction box can sustain for several years or even several decades without damaged and maintain normal supply of electricity, it will become critical equipment for the solar power parts manufacturers making quality assurance testing to their commodities.

Cut Susceptibility Tester

- Equipment conforms to IEC61730 MST12 specification.

- Pre- or post-round can be selected for control wiring connection.

- With weights block’s positioning pin is removed before test; and is inserted in the rear positioning hole for the remaining time.

- Equipped with rings at both front and rear end; used to connect a rope and control the driving direction.

- Use replaceable special cutting chip.

Conduit Bending Tester

Equipment complies with IEC 61730-2:2004 MST 33 specification.

Indoor Multi-Light source of Measurement System for PV Cell

The multi-light source measurement system is capable of execute I-V measurements by Real-Time One-Sweep Method (RTOSM), which not only removes the capacity effect but also meets the requirements of SEMI PV57-1214. The measurement process is controlled by designed program, thus the measured I-V curve, Pmax/Isc/Voc/… etc, could be exported automatically.

This system is applicable to DSSC/OPV/Perovskite measurements.

This system is applicable to DSSC/OPV/Perovskite measurements.

OPV/DSC/Perovskite IV measurement System

The system can measurement the 3rd generation of solar cell IV performance.

The system patent with eliminate capacity effect that can ensure the test repeatability coincidence.

The system patent with eliminate capacity effect that can ensure the test repeatability coincidence.

KING DESIGN specializes in the purchase and sale of PV Test Equipment. We have a vast inventory of PV Test Equipment to better your current process, increasing efficiency while reducing raw materials waste and cost. You can also visit KING DESIGN's showroom where you can find excellent performance PV Test Equipment. Please contact our sales office in Taiwan to discuss the suitability of PV Test Equipment or email us for more information. If you have questions, comments, feedback, or ideas please let us know.