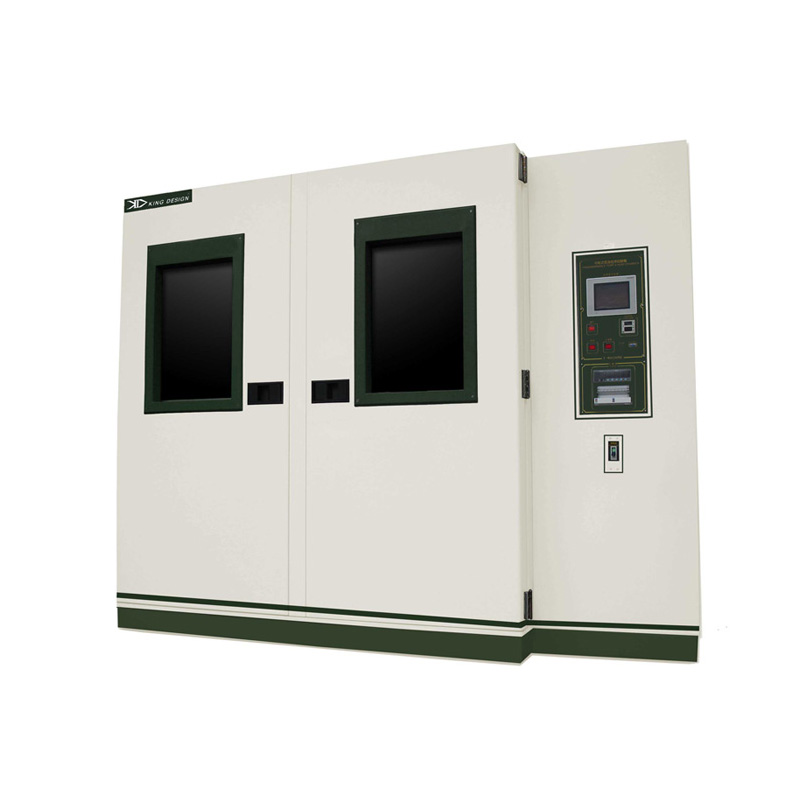

Damp-Heat Tester

Description

- Technical index:

- Power: 380V, 3-, 50/60HZ 110A

- Temperature range: 50°C~120°C

- Humidity range: 20%~95% RH

- Accuracy: 1) temperature ± 0.3°C;2) humidity ± 2.5% RH

- Uniformity: 1) temperature ± 2.0°C;2) humidity ± 3.0% RH

- Uniformity test: measured at T=85°C, RH=85%; set 9 points for temperature measurement and 2 points for humidity.

- Inner wall is above 50 cm; within 20 min after temperature/humidity meets the setting value, the distribution uniformity of temperature/humidity can meet the aforesaid requirement.

- Technical index:

- Power: 380V, 3-, 50/60HZ 110A

- Temperature range: 50°C~120°C

- Humidity range: 20%~95% RH

- Accuracy: 1) temperature ± 0.3°C;2) humidity ± 2.5% RH

- Uniformity: 1) temperature ± 2.0°C;2) humidity ± 3.0% RH

- Uniformity test: measured at T=85°C, RH=85%; set 9 points for temperature measurement and 2 points for humidity.

- Inner wall is above 50 cm; within 20 min after temperature/humidity meets the setting value, the distribution uniformity of temperature/humidity can meet the aforesaid requirement.